UV LED Curing System with DPL patented technology

UV LED curing system with High-Quality Guarantee

As one of the oldest UV LED Curing system manufacture in Europe, DPL starts to design and produce the first cold UV curing lamphouse in 1996. With long-term cooperation with Danish label printing manufacturer -Nilpeter and GW, DPL sold more than 3000 sets of UV Curing system in the world. After 20 years past, DPL UV curing systems is still working on these printing machines.

Experienced DPL Engineers help you improving your curing quality and modify your old machine to produce modern high-value products

DPL UV LED Curing system is much more than just products, we also share our experience on the UV LED curing process with our clients. Our experienced engineers not only help our clients design their new UV printing and coating equipment but also help them to modify their old existing machine by adding new high-value function as holographic UV casting and curing.

OUR KEY TECHNOLOGY ON UV LED CURING PRCOESSING

- DPL Patented Cold UV Curing Technology

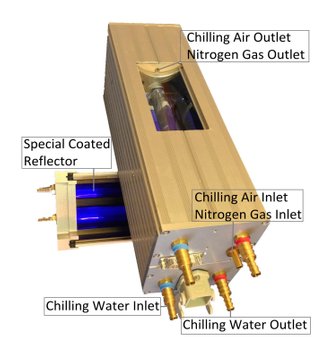

UV Curing temperature control is one of the most important facts which impacts final curing quality, especially for heat-sensitive material curing process. The reason is caused by the heat produced when a UV curing lamp is turned on. For an untreated UV curing lamp, more than 60% energy exhaust is IR, which cause high-temperature on the substrate's surface. Therefore, a UV lamp can reach over 1600C degree, which can easily burn the print substrate like paper, plastic and so on. But with our patented technology, DPL UV Curing system will only heat 5-10 C degree on your printing surface.

- DPL Patented ozone-free UV curing system

DPL UV curing system doesn't have ozone exhaust. DPL UV lamp head uses patented Ozone-Free

design, which got US Pattern and proofed by EU and Danish inspection department.

- High UV Curing Uniformity

When UV light goes through the shutter of a UV lamp head, the highest intensity area is the middle part of the lamp and decreased on both sides of the edge. The UV light intensity different for an untreated UV lamp can reach 30%-25%, which will cause the problem of over cure on the middle material or luck cure on the sides. With our pattern design, each DPL UV curing system can provide uniformity up to 95% on the whole web way from side to side.

- Multi- chilling channel

The main cooling method of DPL UV lamp head is water-cooling, but we also reserve an air cooling channel for chilling air or Nitrogen Gas. Instead of extra cost, our clients can easily contact air to the lamp head.

High-Efficiency UV LED Curing Technology

-60% Energy saving over conventional UV system

-Low operation cost, no lamp shutter on/off stand-by time

-No Ozone exhuast

- DPL Own designed High Power UV LED Module

Each UV LED module at size 41x60mm with UV energy output up to 26w/cm2.

- Individual Power unit to each UV LED module

Automatic controlled Adjustable current with stable voltage to each UV LED module to make sure all module energy output is uniformity and stable

- Longer lifetime for UV LED module

With high efficient cooling system, our UV LED module's standard working lifetime is 50000-60000 hours.

New Price List in 2023

LED Lamp Curing Width (mm) | Wavelength (mm) | Price at EXW DPL Denmark (EUR) |

300 | 385,395 | 3247 |

400 | 385,395 | 4814 |

550 | 385,395 | 5827 |

650 | 385,395 | 6808 |

1000 | 385,395 | 11544 |

Experienced Engineering Design and Innovation Project Management

- Nano/Microstructure Roll-to-Roll fabrication by UV LED Curing technology

Technical consult: Hologram and optical film fabrication is a complex process for the person who doesn't have experience before. DPL help our clients find the right solution according to their specific application to meet their high request on nano/microstructure roll-to-roll fabrication.

Machine installation and worker train: DPL's experienced engineers help our clients install the machines and make a production start-up plan.

-Underwater Lighting system for Plant Growth

-UV LED Curing chamber

Customer designed cost-effective UV/LED curing chamber for different kinds of application, including:3D curing chamber for modules or glass fiber, high-speed curing chamber for glass, wood, touch screen ...

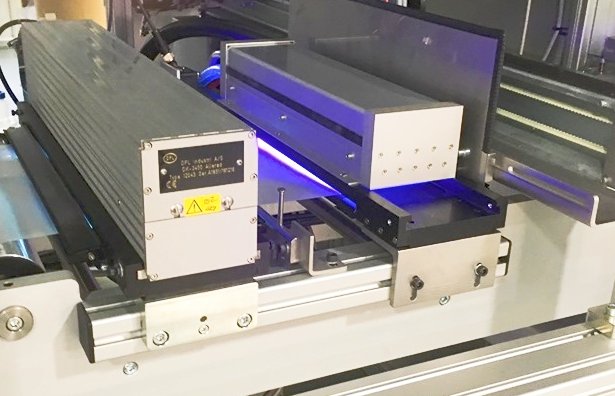

DPL UV LED curing lamp for the printing and packaging industry

In Graphic and label Printing business, DPL UV LED curing system help our clients to solve their production problems: different types of base material - paper or plastic film, short time job or mass job.

DPL small size lamp house with Integrated control system is easy to be installed in different machines.

What can DPL Help you on Graphic printing technology?

As one of the oldest UV LED curing technology developer in Europe, DPL has many experiences on how to design your curing process. DPL specially design UV curing lamp for the graphic printing industry, not only provide higher UV energy output but also better uniformity. So that our system can reach high-quality request for all printing press. Compared with other suppliers, DPL special design UV LED Curing Systems provides a better working lifetime as well. More detail or need technical help, welcome to call us at +45 28871021 or email to dpl@dpl.dk

DPL Underwater UV LED Lighting System for Bioreactor (Patent Pending)

Even though the downstream market for microalgae-based products is growing fast, applications are limited. Commercialization of high-value compounds sourced from microalgae is still challenging due to the low productivity and high power consumption in the cultivation and harvest. Therefore, DPL works together with our partners will build up a highly-efficient and energy-saving production chain to maximize productivity and minimize the power consumption by using our integrated bioreactor with the underwater rotary LED light and heat circulation system.

Innovation Project Induction

Large Scope High Precision UV LED Nanoimprint Replication System (Patent Pending)

Nanofabrication is the essential bridge between the discoveries of the nanoscience and real-world nanotechnology products. Roll-to-roll processing is the most important step for expanding the nanotechnology into a broad range of marketing applications, including flexible printed electronics industry. Most original nanostructured substrate (Called as Master) is created by the lithography mastering system. Due to the production cost and technology limited, the size of these masters are limited, means it cannot be directly used for the commercial roll-to-roll nanofabrication machine for the large scale production. Our object is to build up a larger scope replication machine to create a bigger size working master by using nanoimprint technology and our know-how on UV LED curing technology.

DPL UV LED Holograms Solution

Everyone is pressed for time. Marketers have centred their packaging and labels around glitzy, eye-catching strategies. DPL UV LED Holograms Solution will fill this need by enhancing your brand image and make your products stand out.

Technical consult: Hologram embossing is a complex process for the person who doesn't have experience before. DPL help our clients find the right solution according to their specific application.

Machine installation and worker train: DPL's experienced engineers help our clients install the machines and make a production start-up plan.

Customer designed solution for brand protection by multilayer construction including strong public recognition, inspector level and deep forensic features.

We also provide top quality holographic transfer paper from 25-300gsm with chemical printable varnish coated suitable for different types of print press, customer designed hologram sticker, lamination film.