DPL eAsycure LED System

Advantages of UV LEDs for Manufacturing

UV LED embraces many of the advantages of traditional UV curing for manufacturing processes. It offers advanced capabilities beyond traditional UV curing. First is low heat. UV LEDs do not generate any infrared output that is translated into heat. This is extremely important on manufacturing lines where the introduction of heat changes the chemical properties of the adhesive or coating. This heat can lead to material warping, lack of adhesion and eventually scrap. UV LEDs are a ‘cool’ light source; the only heat is due to UV energy being generated.

The second major improvement is process stability. Manufacturing companies need consistent, stable output. This is now possible with UV LED curing. Traditional UV bulbs degraded over time, which meant their UV output was not stable. Manufacturers dealt with this by over-specifying the amount of energy needed, (which could lead to over-cured, brittle adhesives) or by implementing a maintenance schedule to remove bulbs as a precaution. With UV LED, both of these issues are removed, as they will provide stable UV output consistently over time, leading to better process control and stability.

Why DPL LED System?

UV LED Curing system is more and more popular in the graphic printing industry. Compared with other suppliers,DPL eAsycureTM LED curing system is base on the latest LED curing technology. DPL UV LED curing technology combines with a highly effective and smart construction ensure a stable and perfect curing quality for different types of application.

DPL Customer Designed UV LED module

DPL eAsycureTM LED curing system use our own design LED Modules with wider curing area (41x60mm per unit) and high-resolution optical lens, which can provide high curing energy up to 26w/cm2

Individual Power Unit for Each LED Module

Each LED module has one LED driver with stable voltage and adjustable electric current, which provide high uniformity energy output up to 98%. Independent driver unit also increases LED module's working lifetime and decrease LED energy damping.

DPL eAsycureTM UV LED curing system series is build up with length from 82mm to 2240mm. We also provide custom design service.

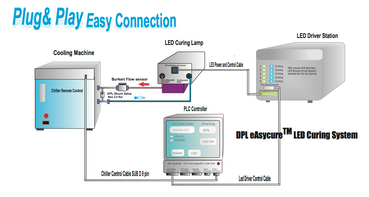

DPL eAsycureTM UV LED curing system includes one set of lamp house, one set of LED Driver, one set of PLC. Clients can use their own chiller or recommended brands. To protect LED Modules's working life, we request chiller should have flower sensor, so chiller will be automatic switch on/off according to DPL temperature sensor in the lamphouse.

Integrated Plug&Play Design

DPL eAsycureTM LED curing systems to use Integrated "Plug & Play" design, which is very easy to be installed. A complete system includes 1 set of LED lamp head/house, 1 set of LED Power Driver Station with a control unit, 1 set of Integrated PLC system with touch screen, which shows all lampworking information.